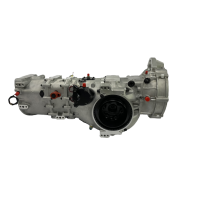

X12

Severe Duty In-line 6-Speed Sequential TransaxleDescription

A huge wealth of experience has gone into this versatile design, which can accept input from either end and be orientated with the Differential above or below the Input Shaft. This allows use in a huge range of applications, from Mid or Rear-Engine GT cars to Off-Road buggies.

Key Design Objectives:

- To be a highly adaptive, very high torque capacity in-line transaxle, with a large emphasis on Off-Road Racing and being able to absorb the associated shock-loads.

- Narrow Flange-to-Flange spacing of 200mm (7.874”), even with a Ramp & Clutch Limited Slip Differential.

- Larger ratio spread than any previous Holinger product.

- 12” Diameter Crown Wheel with highly rigid mounting in order to prolong life and increase the load carrying capacity for a given gear size. This has been achieved by casting a complex cavity around the pinion bearing location, giving low weight but super rigid mounting capabilities, a feature not possible with machined billet housings.

- It has been designed from the outset with paddle shift in mind, featuring internal direct Pneumatic actuation, providing fast, highly positive and consistent gear-shifts. Of course a traditional Gear Lever can also be used where required to comply with regulations. Dual Shift option also available.

Features

- The gearbox is fitted with 6 forward gears, a reverse gear set and a crown-wheel & pinion. All spur gears are profile ground and the spiral bevel is hard machined for increased efficiency and durability. All gears have special modifications to their involute curves for optimal performance under extreme tooth loading.

- Torque rating for 24 hour endurance events is 1100Nm (810 ft.lb). This is not a failure rating but an indication of life expectancy in long events with 100% reliability.

- All gears have an extensive range of ratios available.

- A clutch plate limited slip differential is included, featuring multiple ramp and preload adjustments.

- The internal lubrication system consists of a paper element filter, an oil pump with provision for an external cooler, a spray bar to feed cooled oil directly onto the gears including the CW&P, through-shaft lubrication to all needle roller bearings and oil feed to the differential. The oil level can be checked with a dip-stick.

- Input is via a removable Quill-Shaft, CV-flange, Universal-Joint or can be customised to suit individual requirements.

- Output is available with bolt up CV-flanges.

- Paddle-Shift version as standard featuring internal direct Pneumatic actuation, providing fast, highly positive and consistent gear-shifts. A traditional Gear-Lever can also be used where required to comply with regulations.

- A Dual Shift option is also available: Gear lever and cable are automatically disconnected when using paddles. No danger of being hit with gear lever and additional inertia of these components doesn't compromise shift quality.

- A contactless gear position sensor is supplied for interfacing with an electronic dash display.

- An optional stand-alone gear indicator display is available for cars not fitted with an electronic dash.

- A temperature sensor can be installed on the gearbox (M12x1.5).

- A speed sensor can be installed on the output shaft.

- Case hardened VAR Nickel Chrome steel is used for all gears and shafts.

- The selector forks are manufactured from high tensile, nitrided steel.

- Housings are sandcast Aluminium alloy, heat treated to T6 specifications.

- O-ring seals are used on all joint faces.

- Transaxle weight starts at 110 kg.