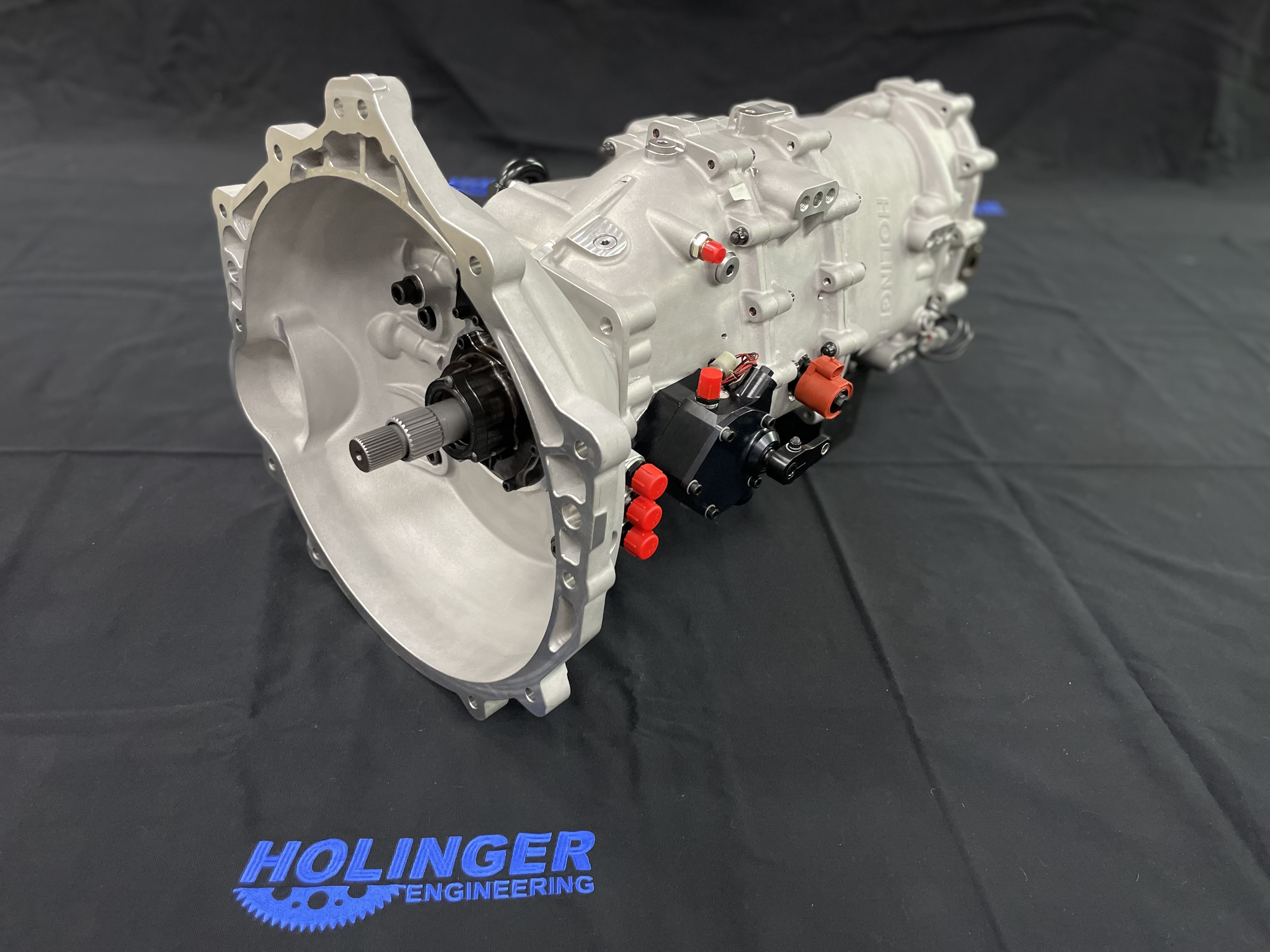

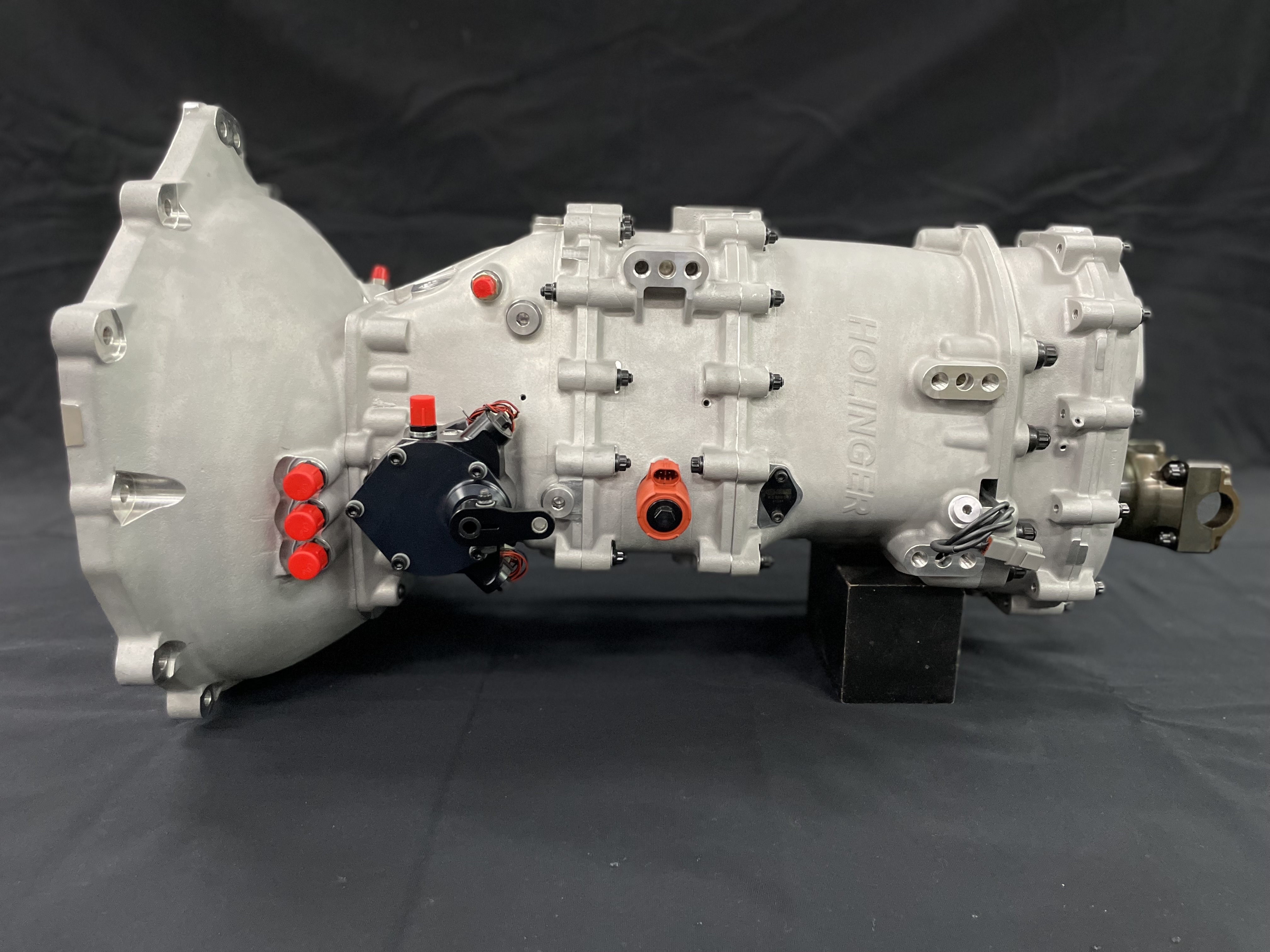

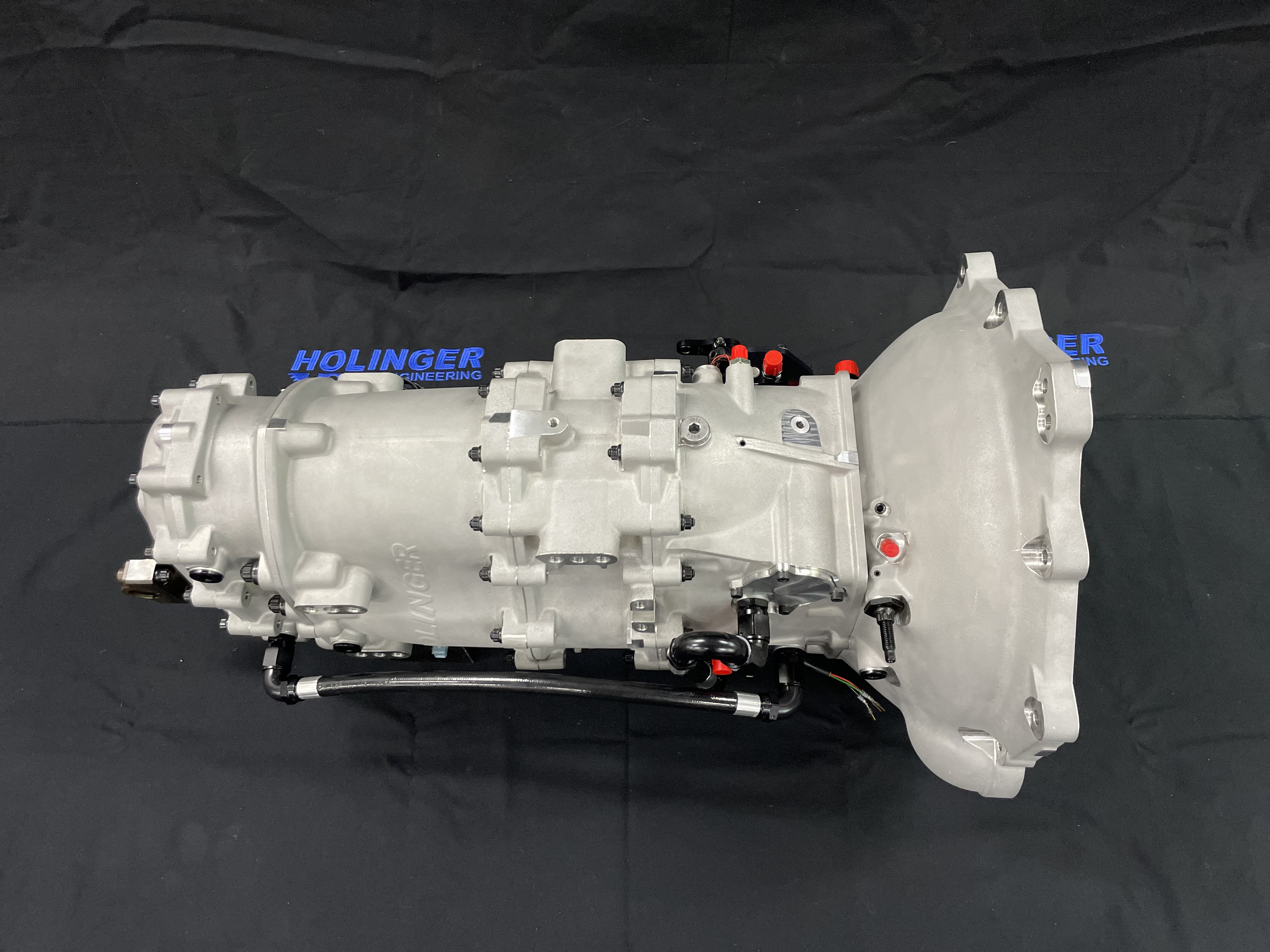

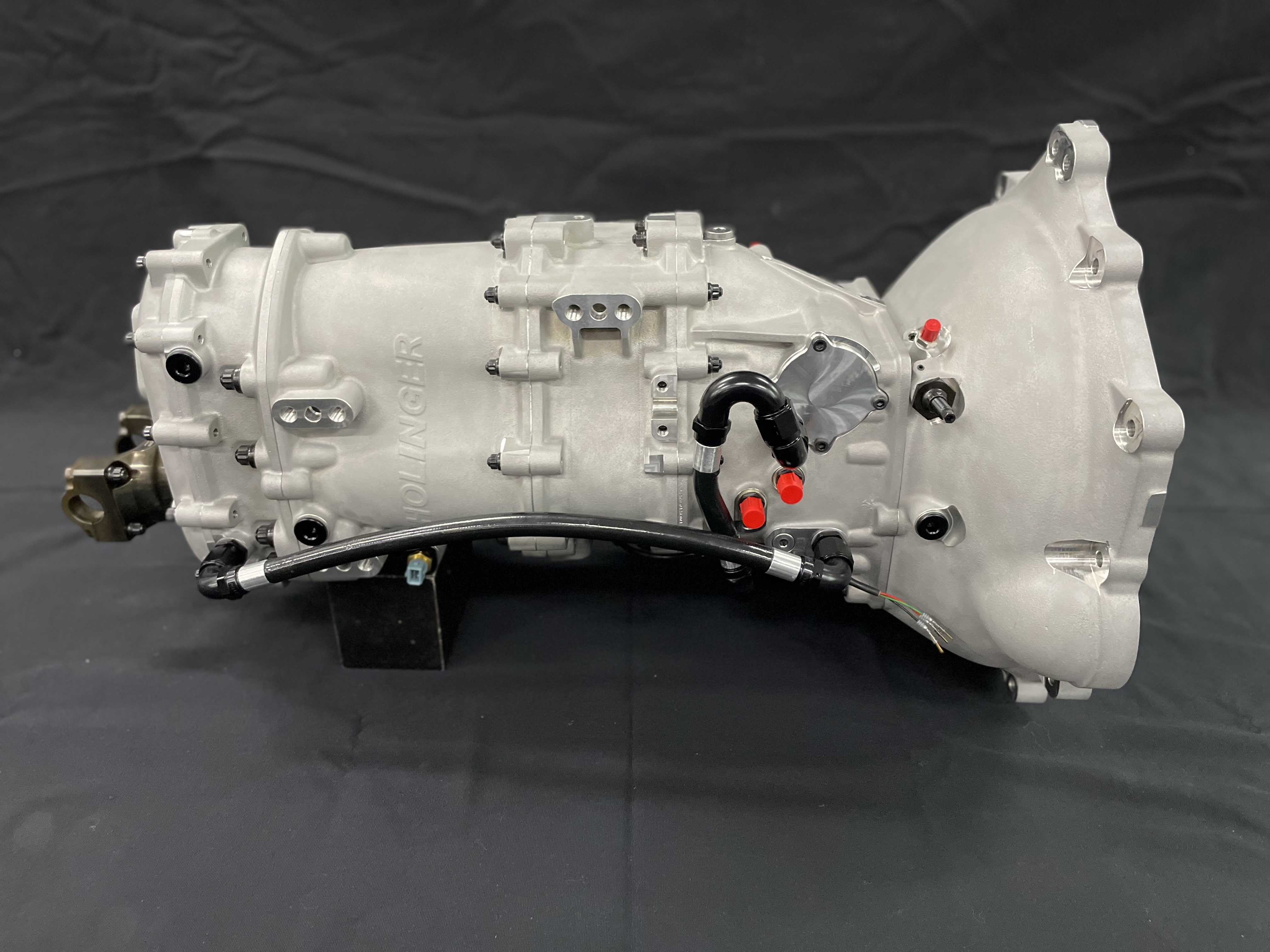

XL6

Severe Duty 6-Speed Dog-change GearboxDescription

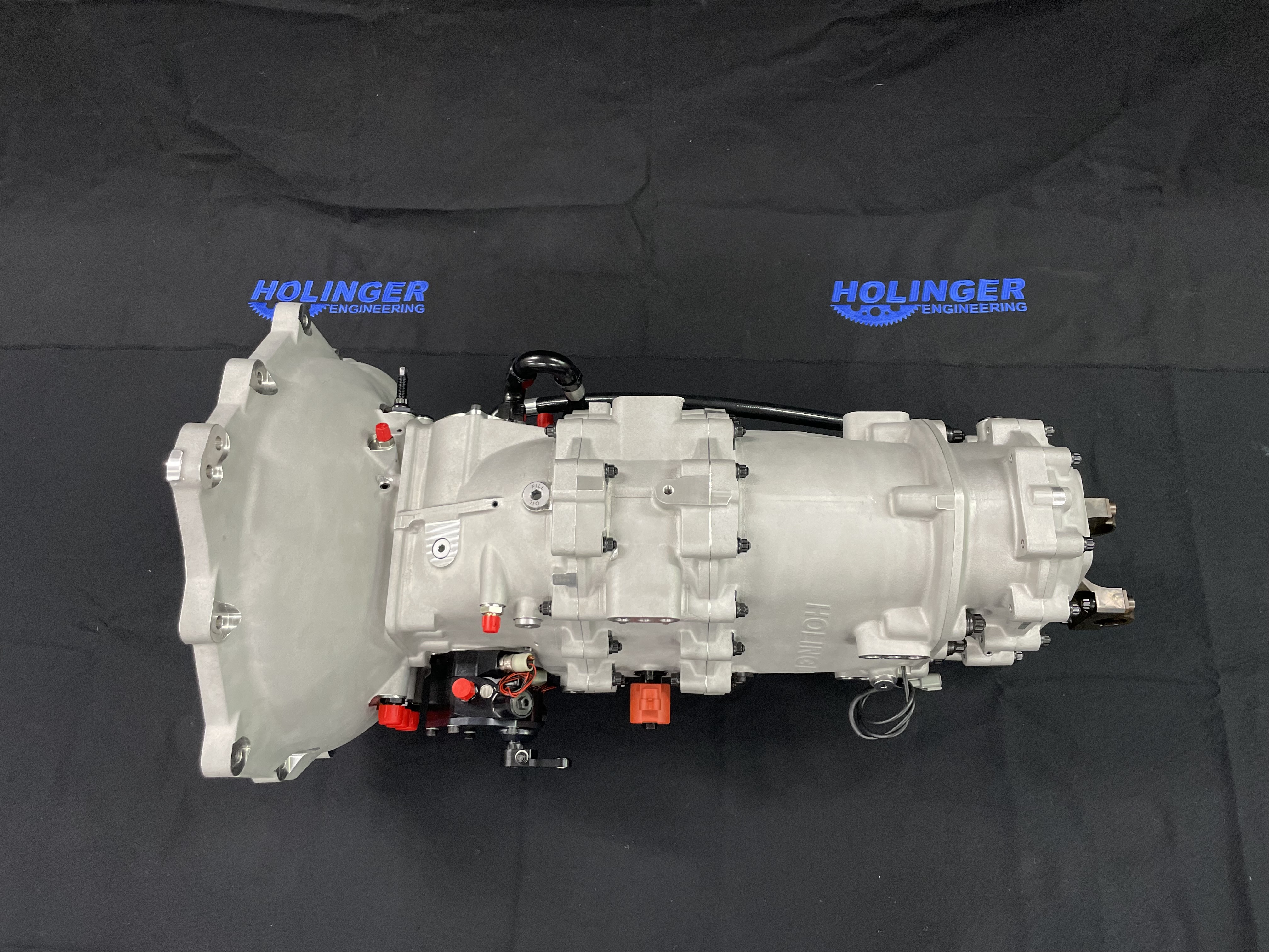

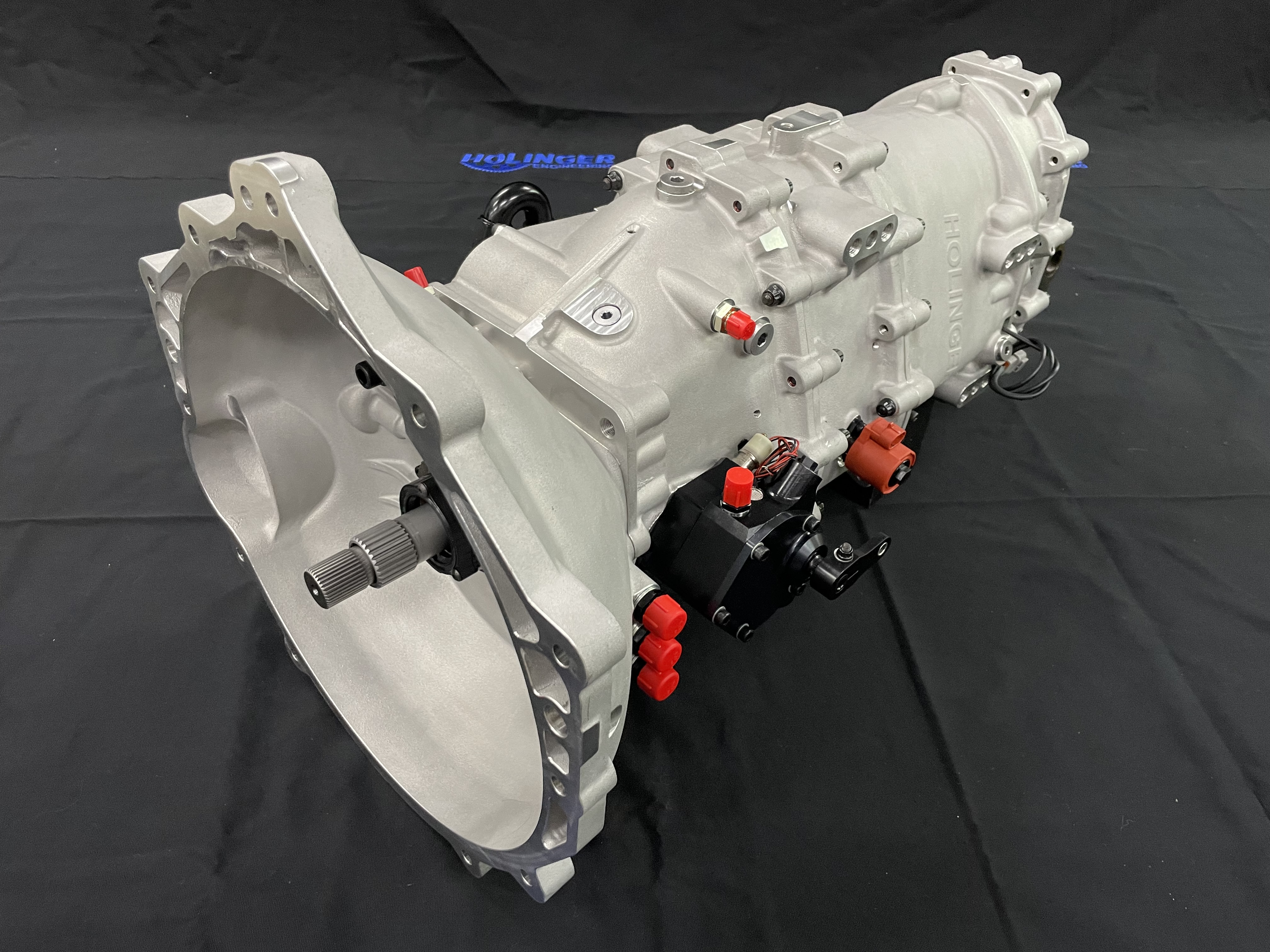

The XL6 takes the gear-set from our X12 transaxle and packages it into an in-line gearbox application witch can be oriented with the layshaft above or below the input. This allows for use in a wide range of applications with very high torque demands.

Features

- The gearbox is fitted with 6 forward gears and a reverse gear set. All spur gears are profile ground for increased efficiency and durability. All gears have special modifications to their involute curves for optimal performance under extreme tooth loading.

- Torque rating for 24 hour endurance events is 1100Nm (810 ft.lb). This is not a failure rating but an indication of life expectancy in long events with 100% reliability.

- All gears have an extensive range of ratios available. Larger ratio spread than any previous Holinger product.

- The internal lubrication system consists of a paper element filter, an oil pump with provision for an external cooler, a spray bar to feed cooled oil directly onto the gears and through-shaft lubrication to all needle roller bearings.

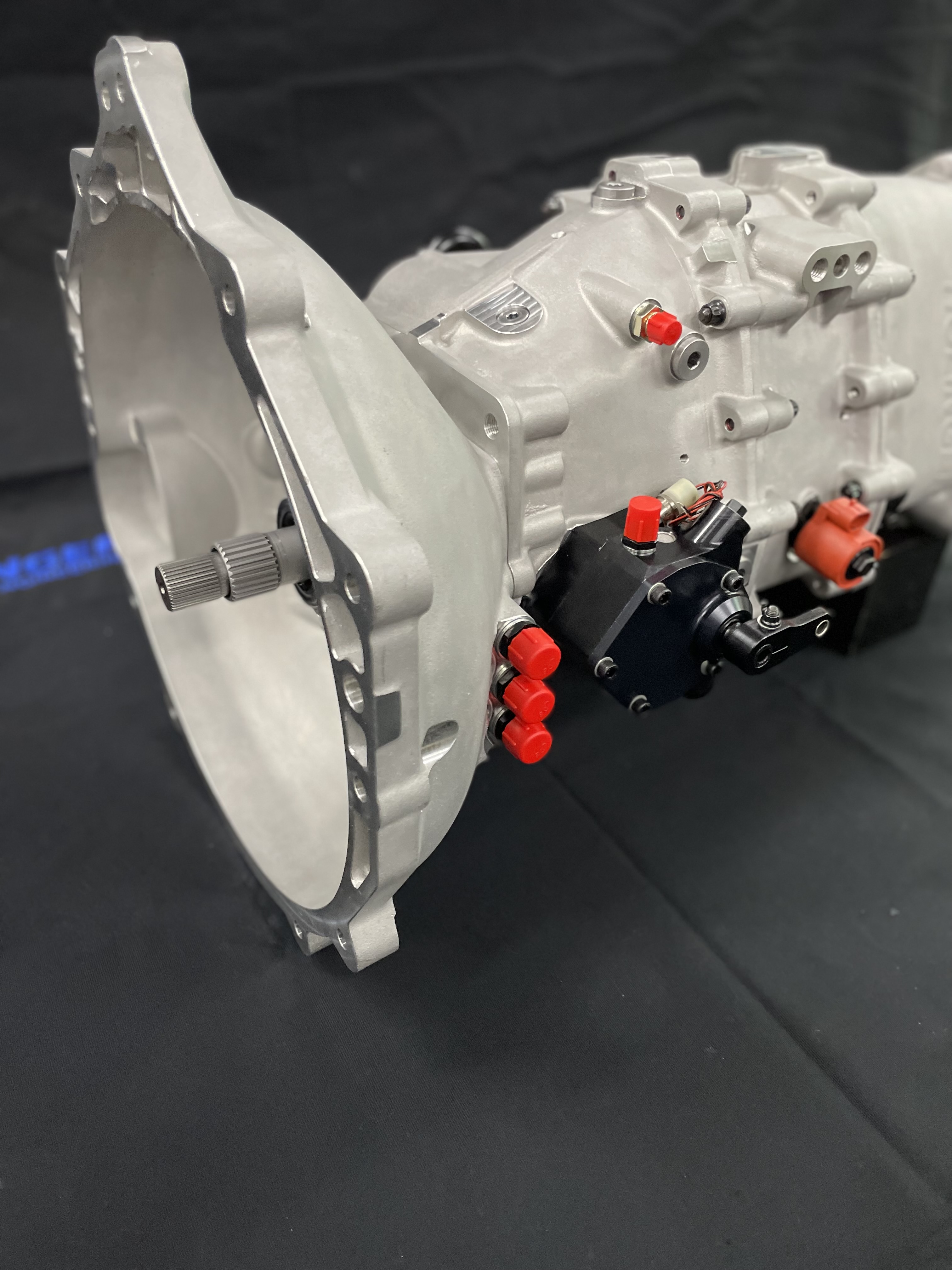

- Input shaft can be customised to suit individual requirements.

- Output is available with bolt up universal joint.

- Paddle-Shift version as standard featuring internal direct Pneumatic actuation, providing fast, highly positive and consistent gear-shifts. A traditional Gear-Lever can also be used where required to comply with regulations.

- A Dual Shift option is also available: Gear lever and cable are automatically disconnected when using paddles. No danger of being hit with gear lever and additional inertia of these components doesn't compromise shift quality.

- Clutch or torque converter bellhousings available.

- A contactless gear position sensor is supplied for shift cut feedback and interfacing with an electronic dash display.

- An optional stand-alone gear indicator display is available for cars not fitted with an electronic dash.

- A temperature sensor can be installed on the gearbox (M12x1.5).

- A speed sensor can be installed on the output shaft.

- Case hardened Nickel Chrome steel is used for all gears and shafts.

- The selector forks are manufactured from high tensile, nitrided steel.

- Housings are sandcast Aluminium alloy, heat treated to T6 specifications.

- O-ring seals are used on all joint faces.

- Gearbox weight starts at 65kg (144lbs).